Blasting with ice cubes

Environmentally friendly , effective and cost-saving

Blasting with ice is an efficient, environmentally-friendly method whereby ice granules are blown under pressure at high speed on the surface to be cleaned. For information we list various blasting methods:

Grit blasting and Water jet

Blasting with grit and blasting with water under high pressure are traditional methods which, however, entail major disadvantages in relation to the environment, costs and safety. These range from high consumption of increasingly scarce water and energy, to contaminants that are blown in the environment uncontrollably, and contaminated residual waste from the used jet medium.

Dry ice cleaning

In the middle of the last century, the blasting with dry ice was developed. Here, deep-frozen CO2 is used as medium, which is blown as granulate under high pressure onto the surface to be cleaned. The problem of the high water consumption was thereby eliminated, as was the energy consumption, but there is still the problem of contaminants that are blown into the environment uncontrollably, and the medium of dry ice is very expensive. In addition to this, the medium only has a limited shelf life, it loses between 5% and 10% of the volume per day due to sublimation. In confined spaces, dry ice can only be used with full mask protective clothing because of the CO2 released, and associated risks.

Wet Ice

Around 2005, the technique of blasting with wet ice was developed. However, it only came to practical development after Coulson Ice Blast perfected this technology in 2017.

How does iceblast work?

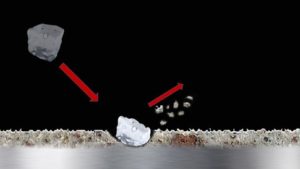

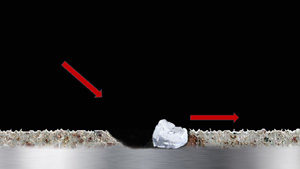

Blasting with wet ice is based on the principle that ice cubes from ordinary tap water to granulate, the size of rice grains, are crushed and these are blown under pressure onto the surface to be cleaned.

There are three phases to distinguish:

- The bulk phase

- The polishing phase

- The rinsing phase